Air humidity reduces

electrostatic charges

Static charges and uncontrolled electrostatic discharges can cost millions, for instance as

a result of damaged products, delays in production or fires caused by sparking.

Controlled humidity reduces the risk of static charge, which means that humidification systems, alongside other ESD protection measures, can contribute to safety and improved

production conditions.

How do static charges develop?

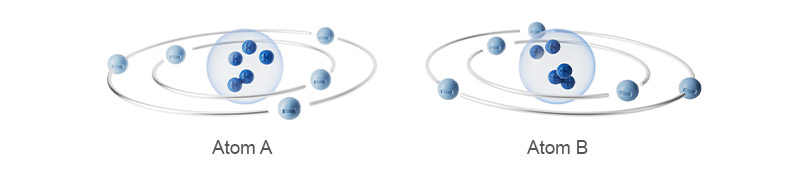

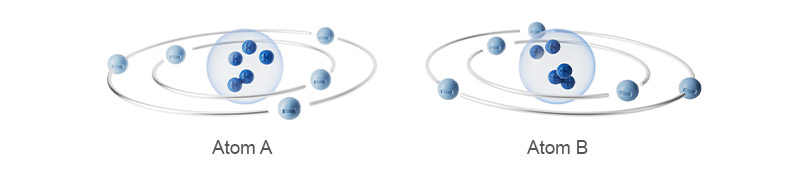

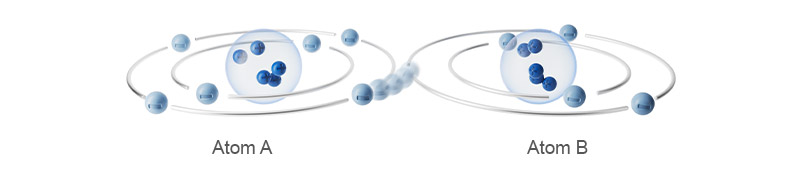

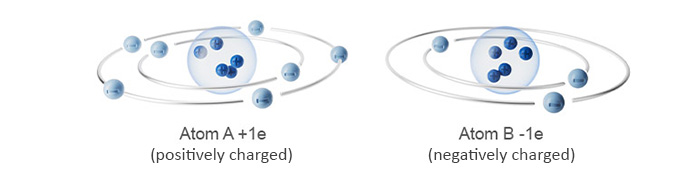

Every object consists of countless atoms. And every atom, in its nucleus, has neutrons and positively charged protons that are orbited by negatively charged electrons in concentric orbits, the shells in a similar fashion to how planets orbit the sun. The number of protons and electrons is usually the same an electrically neutral and stable state exists. However, when two different materials are rubbed together or abruptly separated from one another, so called valence electrons on the outermost shell of an atom on one material’s surface jump to atoms of the other material. This leaves the material itself unchanged, but it loses its electrical neutrality it charges statically. The material from which electrons escape is positively charged, while the material that captures electrons becomes negatively charged. Which substances become positively charged and which negatively depends on the structure of their atoms, in other words the materials’ chemical composition.

1. Atoms A and B are in a stable, electrically neutral state.

1. Atoms A and B are in a stable, electrically neutral state.

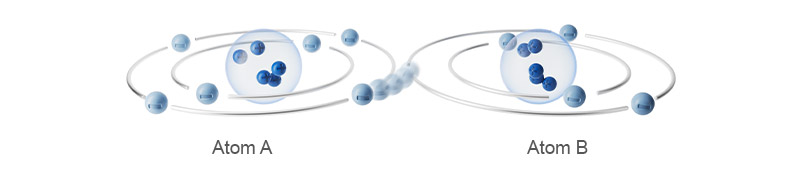

2. Via contact/friction, valence electrons jump from atom B to A.

2. Via contact/friction, valence electrons jump from atom B to A.

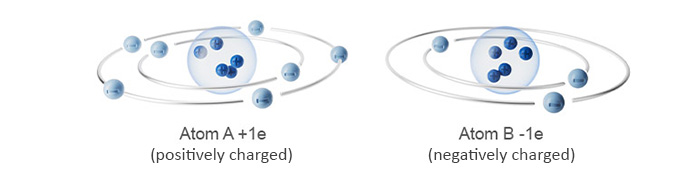

3. Both atoms have lost their electrical neutrality and the danger of an abrupt equalisation with valence electrons from other substances now exists.

3. Both atoms have lost their electrical neutrality and the danger of an abrupt equalisation with valence electrons from other substances now exists.

Generation of static charge in production operations

and its consequences

In manufacturing and production areas, electrical charges are always building up somewhere. This occurs as a result of friction between materials. These can be processes such as rubbing, pouring, shattering, tearing or grinding, the movement of conveyor belts, the unrolling of adhesive tapes, the shifting of plastic containers and many more.

The main cause of problems due to static charge is clogging, adhesion and attracting foreign bodies, which may lead to product contamination and equipment/machinery malfunction. The result: inferior product quality, plus production delays and even stoppages in production. Uncontrolled static discharges occur when a statically charged material or employee comes into contact with an electrical conductor, often a tool or piece of equipment. If there is a lot of friction involved, for example with foil unwinding or bulk materials, such large charges can arise that in the event of a sudden electrostatic discharge such an electric shock can be harmful to health as well or result in damage to components.

In the case of highly flammable materials, an electrostatic discharge can act as an ignition spark under extreme conditions, which in a worst-case scenario may lead to a fire or even an explosion. Consequential damage to components and equipment due to electrostatic discharge occurs particularly frequently in the electronics industry. But electrostatics also significantly hinder production in the processing of paper, plastics, textiles and packaging.