Optimum air humidity for warehousing

Wherever products and goods are stored, wherever objects are archived, a comprehensive air dehumidification system protects the owners from the possible consequences of moisture damage such as clumping, mold and corrosion. The reasons for this are related to the release of moisture from the stored goods themselves or to the ingress of outside air and the associated formation of condensationin the respective rooms.

The risks associated with the ingress of external air are even higher for goods stored in cold storage facilities. Ice formation on all room surfaces endangers the safety of the personnel working there. The condensation that arises in this process can damage the stored goods, and the required hygienic standards can then only be ensured at considerable additional expense. Highly functional dehumidification systems not only protect the product quality, they also ensure the necessary efficiency in the operation of storage and cold storage facilities.

Dehumidification — to prevent corrosion of metallic

raw materials and finished goods

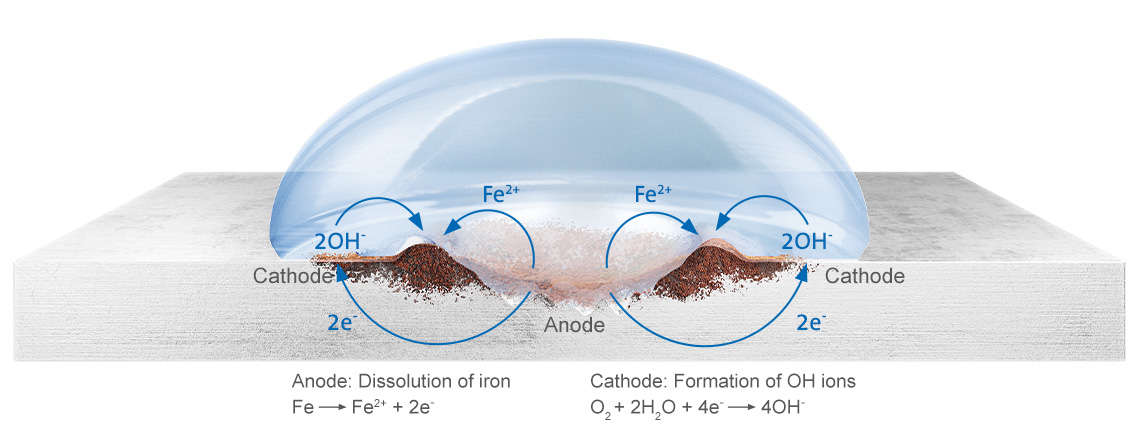

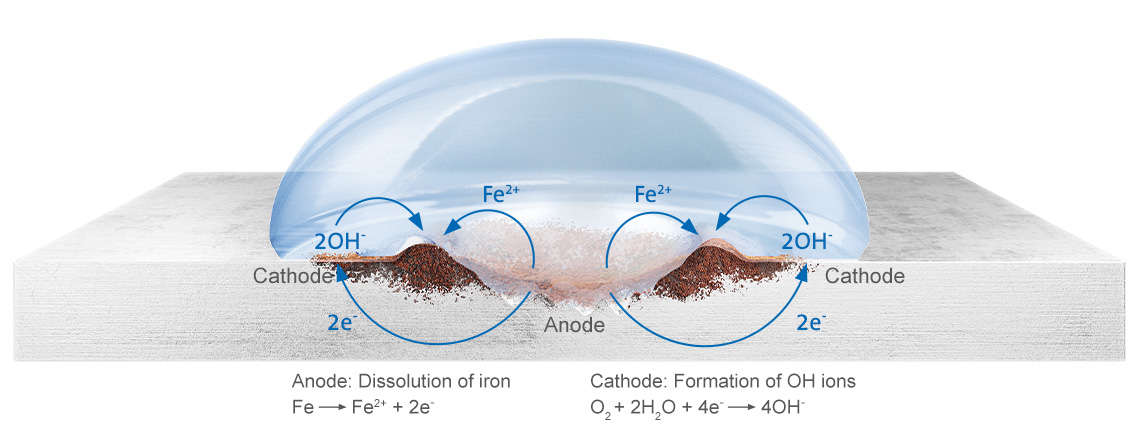

Iron cannot rust in the mere dry air. However, when moisture settles on the metal, oxygen (O2) and water (H2O) begin to react to form hydroxide ions (OH-). To balance the electrons required for this reaction, the iron oxidizes, i.e. it releases its electrons, which are then absorbed by the oxygen. This process produces iron oxide. Where the electrons have been withdrawn, an electron shortage occurs and positively charged iron atoms (Fe2+) are released. These migrate into the water droplets and combine there with the negatively charged hydroxide ions (OH-). In the first step, iron(II) hydroxide is formed as a result of different charges. Further reactions with water, oxygen and hydroxide ions result in ever more continuous reactions from which iron(III) oxide and iron(III) hydroxide are formed. They settle on the metal surface and give the rust its typical appearance. Unlike with metals such as aluminum, the process is only stopped when iron is no longer present.

Humidification — so that hygroscopic stored goods

retain their value

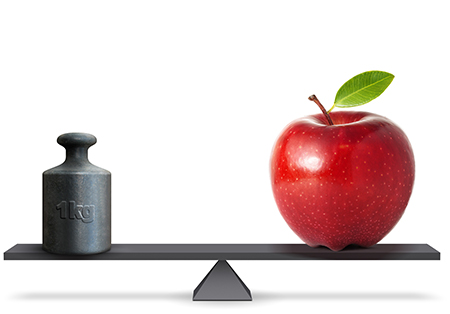

with controlled humidity

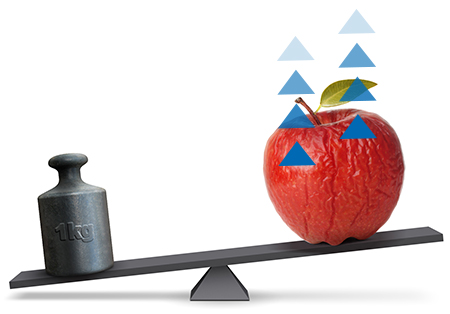

with dry air

As fruit and vegetables dry out and shrivel up quickly at low temperatures, the right humidity must be ensured. An appropriately sized humidification system in both the stockrooms and the display area ensures that fruit and vegetables remain fresh and salable, with no loss of weight.

Maintaining material quality

Wherever (raw) materials are processed or stored, high air quality is a prerequisite for high material quality. Particles suspended in the air, especially dust, can attack the surfaces of the stored products and components or those still to be manufactured. This can result in high costs, especially for valuable materials (e.g. mahogany woods). In addition, glues often do not cure completely or evenly under dry conditions, which reduces the robustness and service life of the end products. A constant air humidity permanently counteracts such threat of deterioration in quality.

Preventing clumping

No matter whether it is the processing of food or pharmaceuticals: If fine materials such as powders or granulates absorb the water vapor present in the ambient air, this can have negative consequences for the manufacturing process as well as for product quality. Powdered materials can thus clump together and block transport routes which can only be unblocked by extensive cleaning work in conjunction with possible production stops. On the other hand, clumping compromises the desired formulation or dosage of the substances and thus also the effectiveness, taste or consistency of the respective end products.

Maintaining material quality

Wherever (raw) materials are processed or stored, high air quality is a prerequisite for high material quality. Particles suspended in the air, especially dust, can attack the surfaces of the stored products and components or those still to be manufactured. This can result in high costs, especially for valuable materials (e.g. mahogany woods). In addition, glues often do not cure completely or evenly under dry conditions, which reduces the robustness and service life of the end products. A constant air humidity permanently counteracts such threat of deterioration in quality.

Preventing clumping

No matter whether it is the processing of food or pharmaceuticals: If fine materials such as powders or granulates absorb the water vapor present in the ambient air, this can have negative consequences for the manufacturing process as well as for product quality. Powdered materials can thus clump together and block transport routes which can only be unblocked by extensive cleaning work in conjunction with possible production stops. On the other hand, clumping compromises the desired formulation or dosage of the substances and thus also the effectiveness, taste or consistency of the respective end products.

Because professional planning is the foundation for functional quality and energy efficiency, we are happy to assist you with your project right from the planning phase.

Steam bath and steam shower

Nowadays, many hotels and health clubs offer spa facilities for the well-being of their guests and members:

A swimming pool, a sauna and more and mor...

Hammam, Caldarium and Rhassoul

A hamam is a steam bath in which a special bathing ceremony is held,

and is an important part of Islamic bathing and physical culture.

The focus is...

Archives

The preservation, provision and safeguarding of manuscripts, books, graphics, pictures, documents and other works of art and culture are the most imp...

Cold storage

When storing foodstuffs such as meat and sausage products, dairy products, pasta and frozen foods, an optimum ratio between the suitable indoor tempe...

Conveyor technology

Regardless of the industry, high conversion speeds, optimum coordination between the individual elements and, above all, reliable functionality are e...

Confectionery

It is in the nature of things (based on physics) that the production, processing and storage process of confectionery primarily depends on the contin...

Food Industry

Consistent air dehumidification has become an indispensable part of the entire process environment in food production, drying and storage.

Drying sys...

Chemical industry

Whether it is a matter of binding raw materials together permanently, pulverising liquids or preventing potential side effects of reactions in applic...

Beverage Industry

Efficiently controlling humidity throughout the production and storage process environment offers companies in the beverage industry clear added valu...

Call Centers

A good room air humidity in a call center not only ensures the employees’ well-being, but also their performance and health. Today, respiratory illne...

with controlled humidity

with controlled humidity

with dry air

with dry air