Air dehumidification in the food industry

New Technical Brochure on Air Humidity in

Production and Storage

Compliance with strict hygiene guidelines is essential in maintaining consistently high product quality in the production, processing, packaging and storage of foodstuffs. At the same time, besides good indoor air quality, ensuring constant and narrowly defined indoor temperatures and humidity is often crucial in ensuring that production processes run without disruptions. However, these parameters are continually being influenced by moisture inputs from warm, humid outdoor air as well as from the release of moisture by people and products. Depending on the type of food and its processing, there is a wide spectrum from “high indoor temperature with high humidity” to “low indoor temperature with low humidity”.

Especially where hygroscopic substances such as powder, flour and sugar are used and processed, low humidity is of utmost importance in order to avoid product clumping and production losses. The brochure deals specifically with the topic of “Ensuring low indoor air humidity in the food industry” in theory and by means of examples. Various processes and techniques for particularly reliable, efficient and economical air dehumidification are presented.

Depending on their functional principle and capacity, the dehumidifiers to be used for this purpose can also remove very large quantities of water vapour from the air in a very short time and thus permanently ensure all air humidities required — from medium to very low.

Technical brochure::

Humidity in Manufacturing

This brochure provides information on what is important to ensure the environment is optimally conditioned, what needs to be considered and what solutions are available.

A little thermodynamics: How dehumidification works

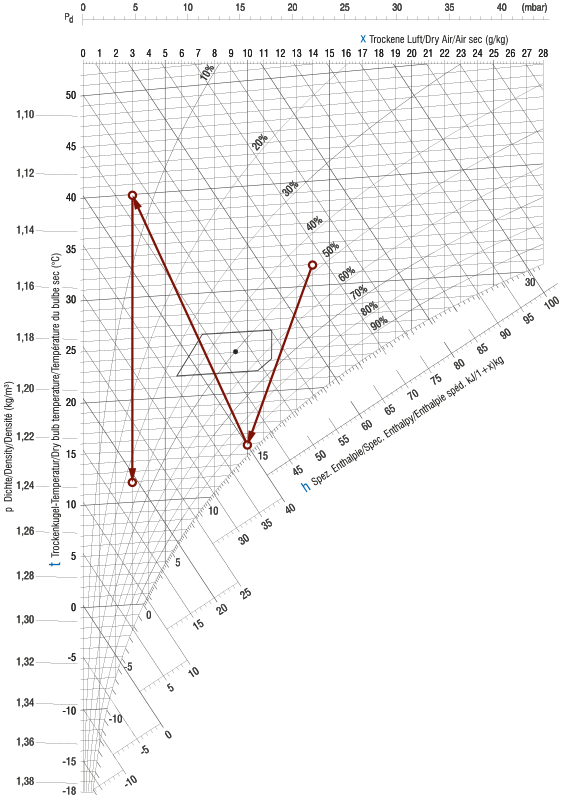

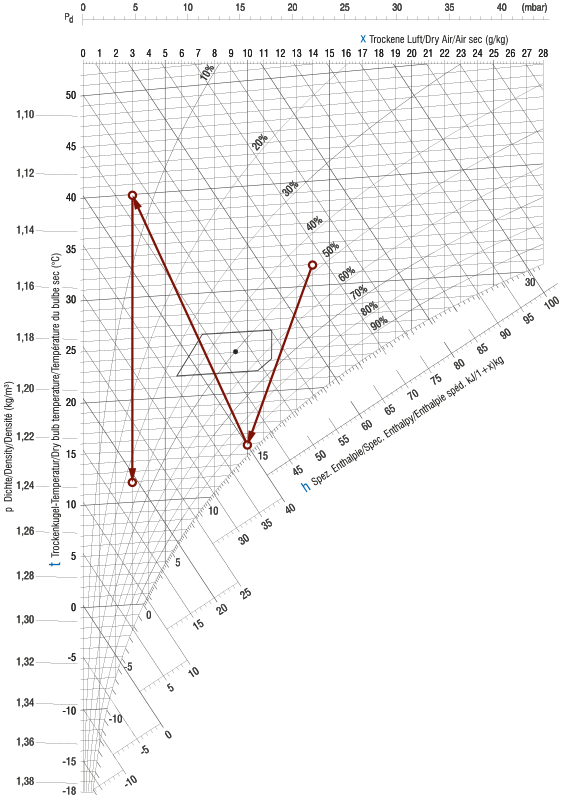

In thermodynamics, the variables of enthalpy (h), temperature (t) and humidity (x) are inextricably linked. These variables are shown in a “h,x diagram”. Enthalpy h refers to the total heat content of the air, consisting of the air temperature and the water vapour present in the air. For humidity, a distinction is made between absolute humidity x (g of water vapour in the air per kg of air) and relative humidity. The relative humidity (φ) indicates, as a percentage, the degree to which the air is saturated. When it comes to dehumidifying air for a process or to ensure specified target indoor air conditions, the following typical challenges arise.

Example 1

Ensuring an air humidity of 50% at an indoor temperature of 20°C. Through the processing of a foodstuff, 2 g of water per kg of air is constantly released into the indoor air (20°C, x = 7.2 g/kg). This water is absorbed by the air as water vapour. However, this causes the indoor air humidity to rise to a value of now about 85% and at the same time the indoor temperature drops to about 15°C. By setting up and operating a dehumidifier (e.g. a condensation air dryer) inside the room, which constantly draws in indoor air and dehumidifies it, the required room conditions are maintained.

Example 2

Dehumidification of an air volume flow to 12°C and a humidity of 3 g/kg

(red curve in the h,x diagram)

Many production processes and the storage of foodstuffs require low temperatures as well as very low humidities. It is assumed that an outdoor air volume flow with a temperature of 32°C and a humidity of 14 g/kg (47%) is to be dehumidified to a supply air condition of 12°C and a humidity of 3 g/kg (35%). An adsorption dryer is used for this purpose. The change of state of the outdoor air to the supply air follows the course of the red straight line in the h,x diagram. Step 1 is a pre-cooling and pre-dehumidification of the air to 15°C and a humidity of 10 g/kg.

In step 2, the air is dried in the adsorption dryer to a humidity level of approx. 3 g/kg, which raises the temperature to about 40°C. In the final step 3, the air, which is now dry, is recooled to the supply air temperature of 12°C.

The brochure contains further examples of air drying in industrial applications, more detailed information on typical areas of application, technical working methods and properties of condensation and adsorption dryers:

The importance of air humidity in production and storage

The brochure contains further examples of air drying in industrial applications, more detailed information on typical areas of application, technical working methods and properties of condensation and adsorption dryers:

The brochure contains further examples of air drying in industrial applications, more detailed information on typical areas of application, technical working methods and properties of condensation and adsorption dryers: