Avoiding suspended dust

through air humidification

Dust formation is a troublesome everyday phenomenon in storage and production operations as well as in grinding, moulding or pressing processes. In the pharmaceutical and food industries, dust can also contain residual traces of materials or ingredients used in the production process. Particles, pollen and spores also make their way from the outside world into the factory halls when goods are loaded and unloaded or prepared for transport.

Problems in production

Dust is one of the highest cost drivers in industry worldwide because the small particles, which are often harder than steel, can cause abrasive wear on machinery, machine stoppages for cleaning, or inferior products and a failure to meet quality standards.

Dust can also create technical problems such as overheating electronics, sensor function limitations or reduced conveying capacity caused by an obstruction of air flow to the fan. In lubricated or oiled joints, ball bearings or other moving machine parts, dust often mixes with lubricating oil and creates a sandpaper-like film that drastically

increases wear.

Adhesion to packaging material

Processing and packaging with plastic films attracts large amounts of dust. This is due to friction in the manufacturing process, which causes synthetic materials in particular to take on a positive or negative electrostatic charge depending on their composition. Dust particles carried around by air currents also take on a positive or negative charge through contact with different objects. In physics, Coulomb’s law states that positively charged particles are attracted to negatively charged objects and vice versa. This force, called adhesion, is stronger the closer the molecules get to each other. Dust therefore adheres particularly well to smooth surfaces such as foils or films if they are electrostatically charged.

In the pharmaceutical industry, electrostatic charges caused by friction during mixing, filling or tableting attract more dust, leading to unwanted contamination of medicines and pharmaceutical products.

Health risks

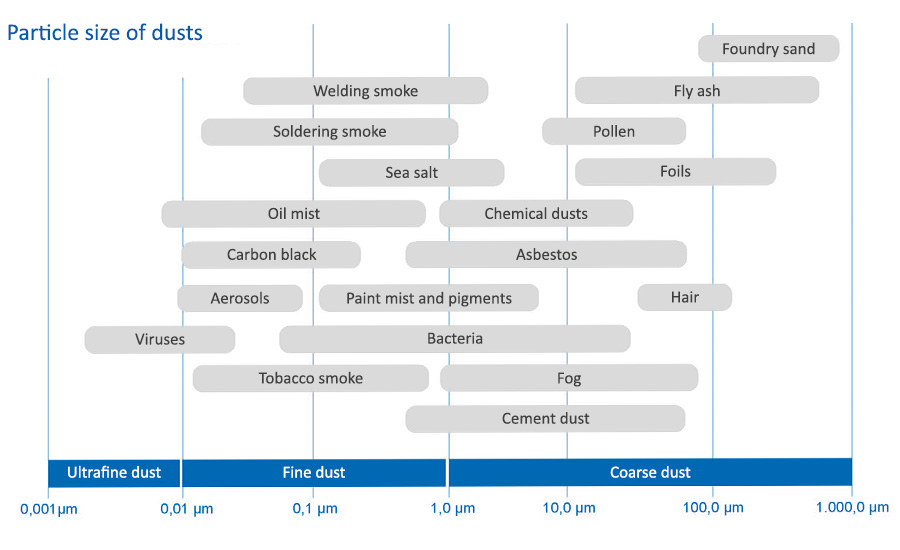

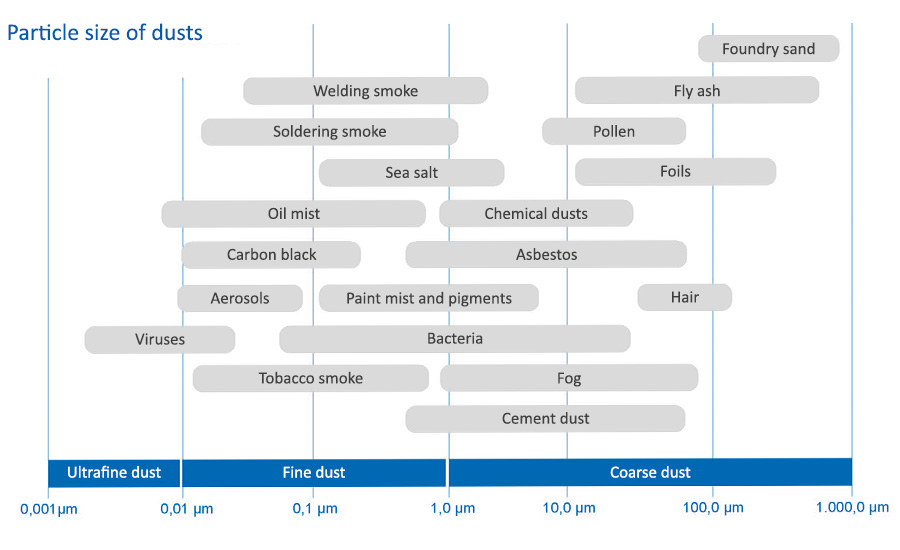

Dust consists of tiny particles of dry solids that can remain suspended in gases, especially in the air, for a long time. By definition, it is a component of suspended dust, which also includes smoke and soot particles.

From a health perspective, the size of the dust particles is crucial. While coarser particles stick to the nasal hairs or the mucous membranes of the nasopharynx, the body's own filtering effect is not sufficient for fine dust with a diameter of less than 10 micrometres. Fine dust travels through the trachea and bronchial tubes deep into the lungs, where it can cause respiratory symptoms and asthma. Ultra-fine particles with a diameter of less than 0.1 micrometres sometimes even make it through the fine branches of the lungs and into the alveoli, from where they can only be removed very slowly or not at all. In the worst case, this can lead to pneumoconiosis, which is one of the most frequently recognised occupational diseases, and whose function is impaired by scarred lung tissue.

Industrial dust can also contain metal particles, minerals such as antimony or kaolin, and chemicals such as barium or tin, which are harmful if inhaled. Contact with certain substances can also cause eye or skin irritation. In addition, some types of process dust can be flammable, which can cause workplace explosions and fires if not handled properly.

Binding suspended dust through air humidification

Industrial dust must be properly filtered and extracted to ensure the health and safety of employees, keep machinery in good working order and comply with government regulations. Air humidification can assist and optimize this process by reducing the amount of suspended dust through dust binding.

The way it works is that dust particles tend to hover longer in dry air. Above a certain humidity, the water in the air condenses on the particles, making them heavier and causing them to sink to the ground. This turns suspended dust into dust precipitation, which is heavier and therefore more difficult to stir up.

In addition, at a relative humidity of around 50 percent, surfaces attract less dust and remain free of particle deposits for longer because they are less likely to become statically charged. Instead, they continuously release their excess charge to the water molecules in the air because water is a good electrical conductor.

If the relative humidity is constantly between 40 and 60 %, this also has a positive effect on the well-being of the employees. Typical effects of dry air such as dried mucous membranes, respiratory diseases, burning eyes or nosebleeds are counteracted.