Indoor humidity

The “Golden Mean” of 40–60%

Excessive relative indoor air humidity during the heating period can favour the formation of mould, leading to corresponding structural damage. This is generally known. Less well known, however, is that excessively low values can also be harmful. The right solution is the proverbial “golden mean” — more precisely, the range between 40 and a maximum of 60% relative humidity.

In practice, planners, builders and landlords of properties often still believe they should aim for the lowest possible indoor humidity level in order to preserve the building structure. In insufficiently insulated buildings, this is the easiest way to reduce the risk of mould growth. Depending on the thermal insulation, there is a risk of structural damage starting from a indoor air humidity of 60%. But that is only one side of the coin.

Excessively dry air makes people ill

During the heating period, the necessary ventilation with cold, often dry outdoor air reduces the indoor air humidity. As a result, the relative indoor humidity can drop to values below 30%. In humans, excessively low humidity in indoor air leads to drying out of the mucous membranes in the mouth, nose, throat and eyes, which in turn leads to an increased risk of infection. Excessively dry air increases the risk of influenza. At the very least, it favours the transmission of influenza viruses, which show higher rates of both survival and infection under these circumstances. In addition, people become more sensitive to all other kinds of air-borne elements, such as dust, allergies and asthma.

From a health perspective, an indoor humidity of 40% or higher is ideal. Values above 40–45% humidity, however, are not beneficial for normal applications during the heating period, as this can only be achieved with a high expenditure of energy for humidification and no additional benefit is gained. In order to meet health requirements and at the same time avoid structural damage, Fachverband Gebäudeklima e.V. [Trade association for buildings and indoor air quality] and experts from the health sector recommend keeping the relative indoor air humidity in an optimal range of between 40 and max. 60% all year round.

The optimum between maximum and minimum humidity

It is still true that building materials should be as dry as possible from a purely material-related viewpoint. However, modern thermal insulation allows the ingress of moisture into the building fabric to be so significantly reduced that at 40 to 50% indoor air humidity, moisture-related damage is no longer to be expected.

Of course, higher indoor air humidity during the heating period must be avoided by means of sufficient ventilation (e.g. moisture protection ventilation in accordance with DIN 1946-6).

However, when there is a high density of people, the ventilation requirement with regard to the necessary removal of pollutants and air quality is higher than the air volume flow for moisture removal (exceptions are damp rooms such as bathrooms, kitchens, swimming pools, etc.).

For healthy indoor air and good thermal comfort levels, it is essential to consider the minimum humidity. The expectation that people should adapt to the requirements of buildings is absurd. Buildings are made for people, and must be designed accordingly.

Nowadays, modern buildings and building technology open up the possibility of finally taking the basic needs of the human body fully into account when it comes to indoor air humidity. From a biological perspective, the mucous membranes that are in close contact with the indoor air — e.g. in the eyes, nose and throat — must be kept moist at all times so that they can reliably fulfil their function. A relative indoor humidity in the range of 40 to 60% can play a decisive role in this.

Yet this is not the only reason why it makes sense to maintain a minimum indoor humidity, but also with regard to the microbial load in the building. Based on the findings of many hygienists, the consequence of (material) dryness and high degrees of cleanliness (= lack of nutrients for microbes) is not a microbe-free surface, rather it is an agglomeration of microbes with reduced species diversity, in which critical or undesirable germs may dominate. Many of these germs are “dry-resistant” bacteria, which means dry surfaces have hardly any effect on them. In the effort to minimise indoor humidity, the following common myths certainly also play a role: Mould and bacteria need high humidity levels to grow, and low humidity prevents this accordingly. Or else: Moisture can only penetrate materials if the air humidity is high. These are misconceptions. In reality, high humidity levels alone are of no use to mould and bacteria, as they need water in liquid form to multiply.

If it is not possible to strike the necessary balance between required ventilation rates, on the one hand, and ensuring the minimum indoor humidity, on the other hand, there are many solutions that can ensure a indoor humidity of 40% in a hygienic and energy-efficient way.

Direct and indirect indoor humidification

Various systems and technologies are used to ensure healthy indoor humidity. In general, air humidification systems are designed in line with two basic principles:

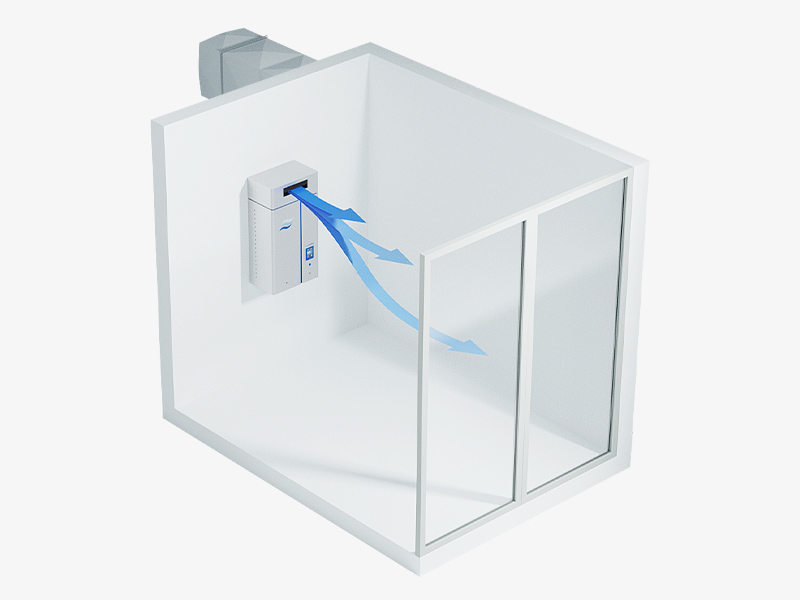

- Direct humidification: Stand-alone humidification systems are installed and operated directly inside the room to be humidified.

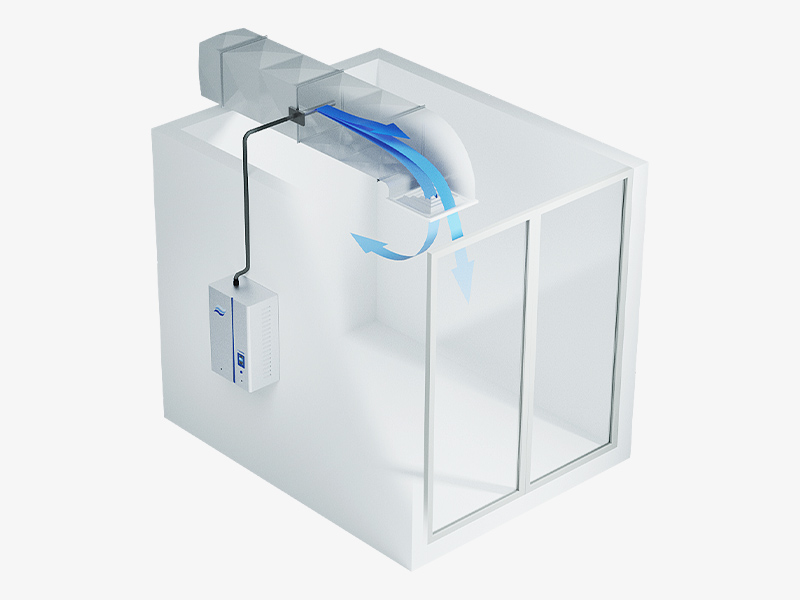

- Indirect humidification: The air is humidified in the chambers of an Air Handling Unit (AHU) and fed into the workrooms via ducts and outlets. Steam and ultrasonic as well as high-pressure nozzle systems are used for both variants.

Whether the desired air humidity in a room should be provided directly or indirectly always depends on the requirements and the conditions on site. A combination of indirect humidification for the basic humidity and additional direct humidification at specific points may even be useful under certain circumstances. In older existing buildings, indirect humidification can only be realised at great expense because ventilation systems are either absent or, if present, too small. Direct indoor humidification is therefore a good alternative for renovations in these cases.

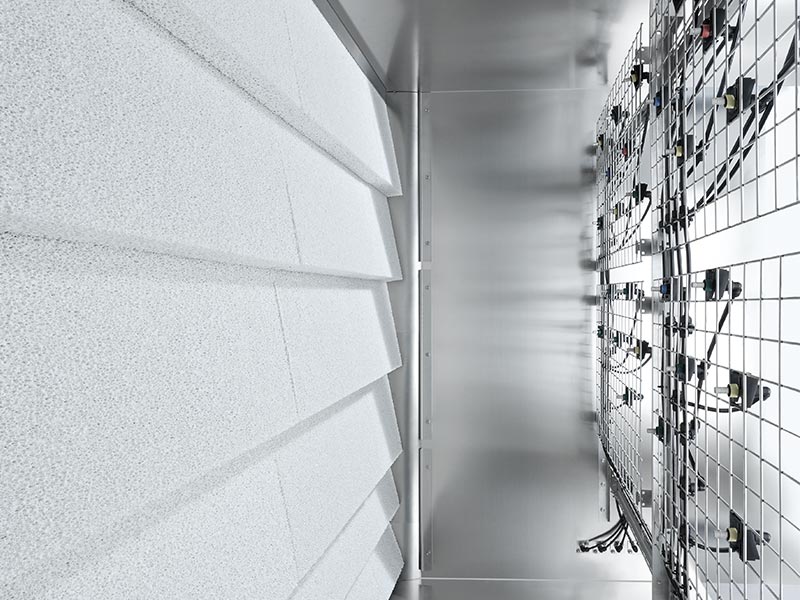

Humidification systems for buildings with AHUs

Selecting the necessary equipment technology is based on the aspects of hygiene, maintenance costs, energy costs and the available humidification distance. Although recirculating spray humidifiers (air washers) were the most common system type just a few years ago, the market has changed considerably in this area. The hygiene requirements for AHUs have led to a rethink: away from the recirculating water principle with all its maintenance necessities towards systems that work exclusively with treated fresh water.

Electric steam humidifier

Electric steam humidifiers are often used in AHUs with small air volume flows. This is due to their short humidification distances and lower investment costs. Depending on the design, they can be operated using tap water or water obtained from reverse osmosis. Only steam humidifiers are used in hygienically sensitive areas, e.g. hospital operating theatres, in accordance with DIN 1946-4. Electric steam humidifiers are relatively inexpensive to purchase and maintain and are also hygienic, provided they are installed and operated correctly. The steam humidifier works isothermally in the air flow, i.e. while maintaining the air temperature.

Hybrid and high-pressure humidifiers

Above a medium air volume flow, the ratio of investment costs to power consumption becomes less favourable for electric steam humidifiers. Therefore, hybrid or high-pressure humidifiers are usually used in these cases. They combine hygienic operation, low maintenance costs and good controllability with a significantly lower power requirement. In this case, water is not heated to 100°C and evaporated as in the case of steam humidifiers, but is atomised at high pressure (high-pressure humidifiers operate at pressures of up to 130 bar, hybrid humidifiers at up to approx. 8 bar).

Hybrid and high-pressure humidifiers are adiabatic systems, where the air temperature is reduced by the evaporation during the humidification process. Therefore, additional heating is usually required. This can be sourced inexpensively through heat recovery or the heating system. Part of the cooling energy can be saved through this evaporative cooling during the summer if the outdoor air conditions are favourable (hot and humid weather conditions are unsuitable for this).

But there are also some misconceptions that need to be cleared up. Since all systems require evaporation enthalpy, they all have the same energy requirement for humidification. The only question is from which source and at what cost the energy is provided. In the case of evaporation in the room, the corresponding amount of energy needs to be provided through static heating, so it is by no means more energy-efficient, or even possible, without energy input, as is sometimes suggested.

Recirculating spray humidifier

The recirculating spray humidifier is still used to this day where large quantities of air have to be humidified (e.g. in the painting, paper and textile industries) and the substance load in the air is high. The maintenance effort depends to a large extent on the water and air quality. Circulating spray humidifiers used to be operated based on the principle of dew point control. After preheating, humidification is carried out down to the saturation line and then the desired operating point is reached by means of a reheater. However, this type of control is no longer permissible under Energie-Einsparverordnung [Energy Saving Ordinance]. Energy-efficient systems therefore work with variable spray water supply — adjusted via controlled pumps — and are similar to hybrid and high-pressure humidifiers in terms of the control type.

Contact humidifier

The contact humidifier, which also operates based on the circulation principle, occupies a certain special position. In this system, water trickles over a packing and evaporates on its surface (similar to the way cooling towers work). These systems are more difficult to control and are therefore mainly used for exhaust air cooling (indirect evaporative cooling). However, this system is also used for supply air humidification in isolated applications. Hybrid and high-pressure humidifiers usually use water from a reverse osmosis system, recirculating spray humidifiers — depending on water quality and requirements — softened water or, if necessary, reverse osmosis water.

Steam humidifiers and evaporators are particularly suitable for humidifying individual rooms, e.g. in detached houses. These systems should be adjustable by means of a hygrostat, so that excessively high or low indoor humidity can be safely avoided. It is important that the systems be subjected to periodic maintenance and cleaning in line with the manufacturers’ instructions. Due to the high temperatures, steam humidifiers are usually easier to handle than evaporators.

Hands off “home remedies”

At this point, we would like to issue a strong warning against the use of “alternative humidification systems”. These include, for example, radiator evaporators, indoor fountains and indoor plants, etc. Radiator evaporators work at water temperatures around 30 to 40°C, i.e. exactly in the range where germs multiply best. Indoor plants always provide a pleasant environment, but their humidification capacity is hardly noticeable in a normal office set-up or at home. In addition, drying laundry in the living area is occasionally recommended as a means of increasing air humidity. These “aids” can by no means replace modern air humidification systems, as either too much or too little humidity (e.g. in the case of plants) is released or the release is not properly timed.