Functional diagram of a diffusion fleece

Humidifier unit of the diffusion humidifier

Hydraulic unit of diffusion humidifier

Diffusion humidifier in a family house

Air humidification simply explained:

What is a diffusion humidifier?

How a diffusion humidifier works

Diffusion humidifiers are based on the principle of natural moisture diffusion through a waterproof but breathable membrane. This concept is also applied in modern functional clothing to remove moisture from the body in the form of water vapour. Materials that can only be penetrated by water vapour are used here also. Although the membrane is completely impermeable to liquid water, it is highly permeable to water vapour. This enables very effective moisture diffusion while preventing the air flow from coming into contact with wet surfaces.

Installing a diffusion humidifier is simple as the system can be installed in the plant room without the need for major conversion work and uses the existing controlled domestic ventilation network. The duct element is inserted into the supply air duct of the controlled domestic ventilation. The hydraulic box supplies the duct element with tempered water. Existing heat sources such as underfloor heating, a heating circuit or even domestic hot water preparation can be used to treat the humidifier water energy-efficiently. And with an existing photovoltaic system, it can be self-powered.

Patented diffusion fleece

The patented diffusion fleece is based on a highly-efficient sterile membrane. It is arranged as a compact fleece package through which humidification water flows. Although the diffusion fleece is completely impermeable to liquid water, it is highly permeability to water vapour. This enables very effective moisture diffusion while preventing the air flow from coming into contact with wet surfaces.

Unwanted water components cannot penetrate the sterile membrane. The fleece structure was designed in such a way that only very little space is required for the actual humidification process.

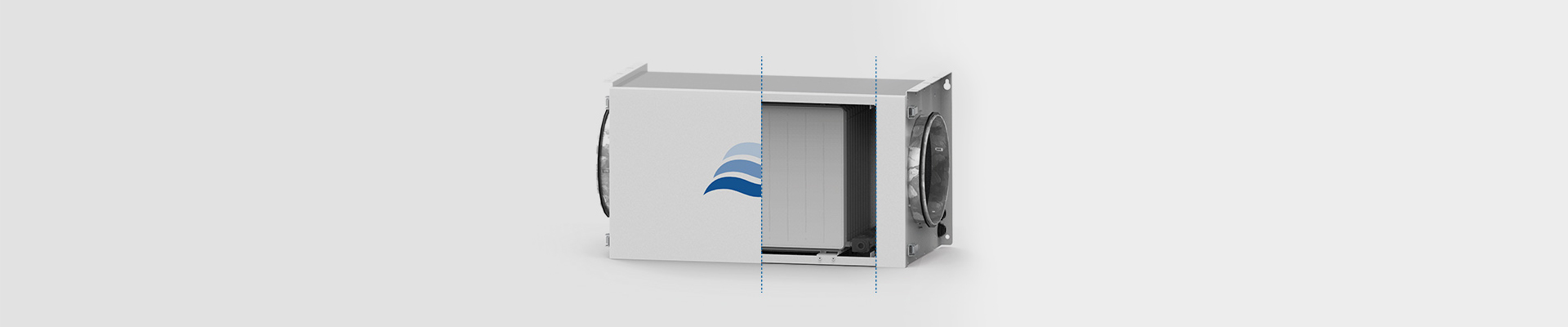

Humidifier unit (duct element)

The aesthetic chassis made of powder-coated sheet steel is used to hold the fleece package and is easy to integrate into the air duct. Matching connection pieces are available in different sizes, making the installation as easy as possible. The required water connections are already pre-assembled. Installation in the air duct can therefore be carried out quickly and accurately.

Hydraulic unit

The unit control and all hydraulic components are combined in the control unit in a compact manner. The humidity values are set quickly and easily via an ergonomic touch-screen display. The control unit can be connected to Smart Home systems as an option. For easy installation, all cable connections are also pre-mounted here.

System structure & model overview

The Condair MD controlled domestic ventilation humidifier consists of the hydraulic unit and the humidifier unit. It is available in four versions and at two humidification capacities (1 kg/h or 2 kg/h). The humidifier unit is installed at least 300 mm above the hydraulic unit in the central supply air duct upstream from the distributor and downstream from any existing silencer. It can be mounted on the ceiling (standard) or on the wall (optional). The hydraulic unit is mounted on the wall at least 300 mm below the humidifier unit using the supplied mounting rails. The water circulating in the humidifier is heated in the hydraulic unit depending on the required humidifier capacity (25 to 45°C). This heating can be carried out using various methods. These methods or the conditions on site define the design of the hydraulic unit:

Humidifier structure

The Condair MD humidifier consists of a hydraulic unit and the humidifier unit. The humidifier unit is installed at least 300 mm above the hydraulic unit with transition pieces in the central supply air duct upstream from the distributor and downstream from any existing silencer. The humidifier unit can be mounted on the ceiling (standard) or on the wall (optional).

Power supply

The hydraulic unit is equipped with a 3-metre mains cable with Euro plug and is connected to a three-pin mains socket 200 to 240 VAC, 50/60Hz. The mains socket must be protected by a separate FI switch (max. 30 mA) and a separate circuit breaker (min. 10A, slow). The control and monitoring devices (humidity and temperature sensor, maximum hygrostat, airflow monitor) are supplied via an internal 24 VDC voltage.

Water drain

The water drain of the hydraulic unit is connected to the building’s waste water pipe via an open drain funnel with siphon.

Fresh water installation

The Condair MD humidifier comes with a filling cup tested by DVGW [German association for gas and water] and can be connected to the drinking water pipe directly.

Leakage kit

If the room where the humidifier is installed does not have a floor drain, installing the optional leakage set is recommended.